WHAT IS TRAY CABLE?

Tray cable consists of two or more insulated conductors cabled together with a ground conductor and covered with binder tape and jacket. It can be installed in cable tray, raceways, or where supported by messenger wire. The cable’s versatility makes it suitable for many different types of applications—indoors or outdoors in both wet and dry locations.

Tray cable can be manufactured in a wide variety of configurations with multiple options for voltage rating, outer jacket, insulation, and shielding. It should be thoroughly tested and adhere to multiple industry standards.

UNSHIELDED VS. SHIELDED TRAY CABLE

Application and installation requirements must be carefully considered when specifying shielded or unshielded tray cable. For some purposes, a shielded cable would be over-engineered—adding unnecessary cost. On the other hand, failing to choose a shielded cable when necessary can lead to damage and additional expenses. For these reasons, it is essential to understand when it is appropriate to choose an unshielded or shielded cable.

UNSHIELDED TRAY CABLE

Unshielded tray cables are ideal for power distribution applications in low electromagnetic frequency (EMF) environments where signal degradation, crosstalk, and other electrical noise are not a risk. For environments with low levels of EMF, unshielded cables offer several advantages:

- They are less expensive to manufacture and purchase.

- They are more flexible and lighter, making them easier to bend and better able to fit into tight spaces.

For environments with high levels of EMF, unshielded cables should not be considered as their lack of protection can cause cable and equipment failure, leading to expensive downtime. Instead, a shielded cable should be chosen to avoid these issues.

WHAT TYPES OF SHIELDS DO TRAY CABLES HAVE?

Tray cables have a variety of shield materials and designs available. All shields provide some crush and corrosion resistance. Their main function, however, is protection from electromagnetic interference (EMI). Service Wire uses two of the most popular and effective shielding methods: corrugated and smooth flat copper tape.

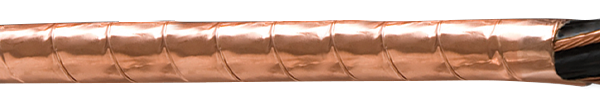

LONGITUDINAL CORRUGATED COPPER TAPE SHIELD

This type of shield consists of a sheet of corrugated copper tape longitudinally applied down the length of the cable core. Although the shield physically covers the core, there is only a small amount of overlap where the two ends of the shield meet—creating a gap that can allow some electromagnetic radiation to leak out.

This is not an issue because the primary purpose of this shield type is to keep external EMI noise outside of the cable. For this reason, corrugated shield is often used in utility applications such as control circuits in substations—enabling them to function without electrical interference from the rest of the substation.

Another advantage of the corrugated copper tape shield is flexibility. The corrugated surface of the shield allows a cable to bend more easily than those with a flat shield, which can get damaged from excessive bending.

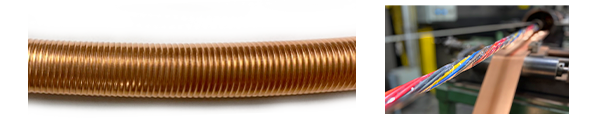

HELICAL FLAT COPPER TAPE SHIELD

Helically applied copper tape shielding is wrapped around a cable core. Service Wire wraps these shields with a 50% overlap to ensure 100% coverage of the core—even when bent—and electrical containment within the conductors. This design provides the path of least resistance for common mode or stray currents to return to ground while also providing the highest level of shielding to combat EMI. In other words, this type of shield keeps current in a conductor and protects the conductor from outside electrical interference.

This is very important for cable used in applications such as variable frequency drives (VFDs) where stray currents can cause damage to both cables and surrounding equipment. To mitigate these risks, the flat shield plays an essential role in properly terminating VFD cable.

A flat copper tape shield is less durable, protective, and bendable than a corrugated shield. It does, however, offer more EMI protection for applications where it is essential.